Resources

An Overview of Six Sigma Methodology

Applying Six Sigma* methodology to improve the relocation process

Six Sigma is often discussed as a way to improve performance, optimize processes, increase quality and improve customer satisfaction. While Six Sigma can deliver all those benefits, there is broad misconception about how success is accomplished and what is required to achieve tangible results. It is hoped that this paper will serve to educate the reader about Six Sigma and how the optimal benefits can be achieved when using a Six Sigma approach, specifically within the relocation industry.

Six Sigma is a methodology born out of necessity in the early 1980s at Motorola Corporation. At that time, Motorola had an urgent need to increase the reliability of its manufactured assemblies. Motorola engineers postulated that if they could select the most reliable parts that went into a product, the completed product itself would then have fewer defects and function longer before requiring service. It was this concept that spawned the Six Sigma methodology. That is, to reduce costs and increase quality, one had to measure a part’s current capability. By understanding the current process and setting goals for the desired performance standards, tangible results are achieved. Moreover, by understanding the source of the defects and reducing variation, the processes can be brought under control and optimized. This is the heart of Six Sigma.

*Six Sigma is a registered trademark and service mark of Motorola, Inc.

Building Blocks of Six Sigma

The Six Sigma framework, the five phases of the Six Sigma process, is known as DMAIC: Define, Measure, Analyze, Improve and Control. If DMAIC is diligently followed and properly implemented, a poorly performing process can be improved to the desired level of output—usually. The DMAIC process is not an answer to every problem, nor is it realistic to think that a very poor performing process can be optimized to perfection. DMAIC can only improve existing processes so much. In many cases, a complete redesign is required to radically improve performance levels. Other considerations that are equally important are: is data available, is there sufficient management support, is the project realistic and can the results be measured?

To gauge the performance of a process, the “Z score,” a single metric that describes process capability, is used. Before understanding why Six Sigma is a great level of performance, it is important to understand the parameters of distributions that are used to calculate this single golden metric.

Figure 1 is a distribution of a particular process performance. Notice that the average—the single most quoted performance metric—is the calculated center of the distribution. If the distribution is normally distributed, as in this case, the calculated center will be close to the graphical center of the distribution. Distributions with normal parameters are also known as “bell shaped” or “Gaussian.”

Equally important as the average is the measure known as standard deviation. Standard deviation is a measure of variation for any given distribution. For a normal distribution, one knows the percentage of the population falling within one standard deviation, two standard deviations and so on. For instance, 68 percent of a distribution’s members occur within plus or minus one standard deviation from the mean. If one were to move six standard deviations from the mean, only three to four members of the population would be present in a million opportunities or measurements. So, if a process were truly Six Sigma, one would see results six standard deviations from the average only three to four times in a million opportunities. It is this concept that gave rise to the Six Sigma name, with sigma being the Greek letter used to represent standard deviation.

The question that might be asked at this point is, “So what? Why do I care if I see only three to four distribution members six standard deviations from the average in a million observations?”

An alternative Six Sigma strategy called "Design for Six Sigma" is used when a process is so broken it can't be fixed or when there is no process in place to start with.

Only measuring an average without taking into consideration variation is a risky proposition. Remember by definition 50 percent of all values will likely fall above and below the average!

To tie the idea together, it is important to take our theoretical distribution and make it practical. Let’s say that the distribution in Figure 1 is the history of several brokers’ market analyses (BMA) over a year as compared to the actual sale price. For instance, one agent working for the broker estimates that a house will sell for $100,000, but the house sells for $105,000. In that example, the agent would have a variance of +5 percent. It is the collection of these measures for all agents in the brokerage of interest that represents the distribution in Figure 1.

BMA variance in this example can negatively impact a relocation program in several ways. First, underestimating the sale price can cause employees to feel their homes are being under-valued, thereby reducing transferee satisfaction. Overestimating the sale price, on the other hand, can cause the property to stay on the market a long time, and ultimately lead a company to take the home into inventory, resulting in increased costs. In addition, overestimating potentially sets an employee’s expectations too high, leading to disappointment if a higher selling price was expected to provide greater purchasing power for the next home.

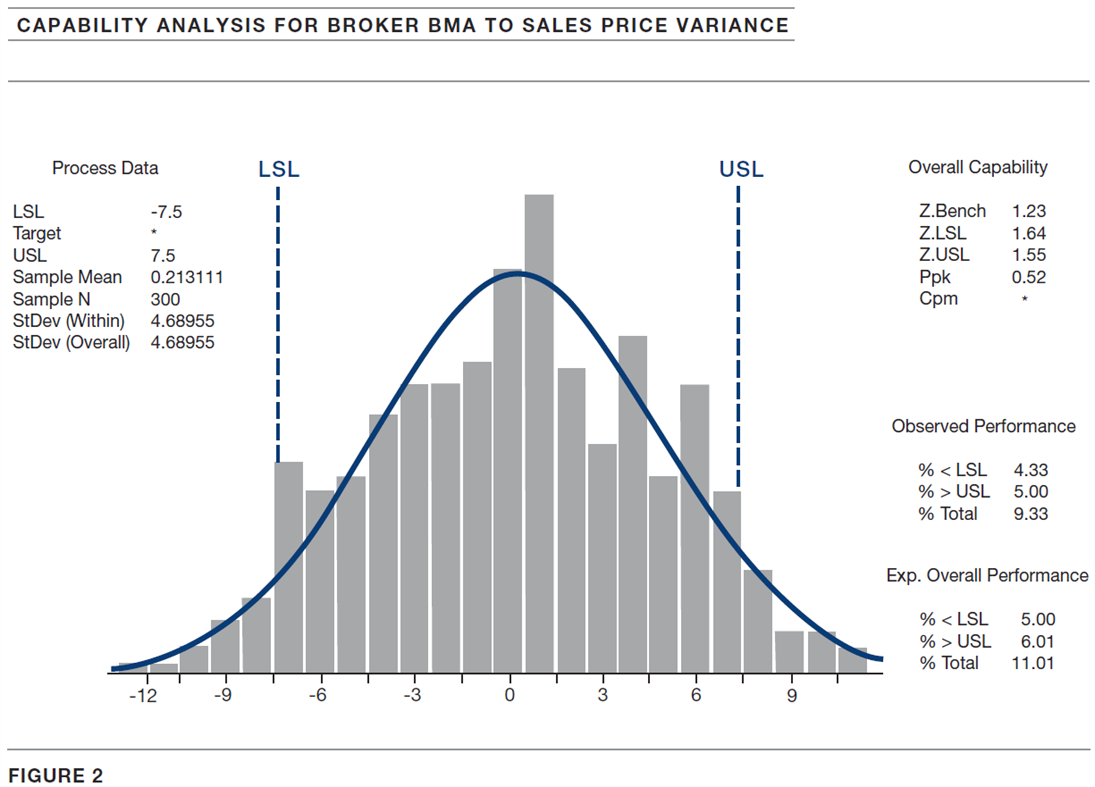

Let’s further define poor performance to be anything that is +/- 7.5 percent. These measures are known as upper and lower specification limits and are almost always defined by the customer. In this case, the relocation services provider specifies to the brokers that all BMA variance must be within +/- 7.5 percent, or it is considered a defect. The defect rate that is achieved over the year is monitored and is part of the evaluation of the brokers’ performance, as well as other incentive and Service Level Agreement (SLA) management

Looking at Figure 2, we can determine the defect rate by measuring the number of homes assessed outside the specification limits. This is the combination of the properties below the lower specification limit and those above the upper specification limit (in this case 9.33 percent). The graph also includes both an observed (actual) and expected (statistically estimated) defect rate. The observed is the percentage of the population outside the specification limits. The expected defect rate is a calculation comparing the distribution parameters to a distribution occurring a million times. Since our distribution is composed of only 300 measures, it could be that the resulting performance is much different from what could be expected if the measurement were taken over and over again. The expected performance is typically not as good as what is observed, due to shifting variation over time. The expected rate is a predictive measure, whereas the observed rate is a measure of current performance.

Finally, notice the metric “Z-bench,” which is the process capability of the distribution and is the same as process sigma. In our example, the process capability for the brokerage is 1.23 sigma. If six is deemed perfect, then we are about 20 percent of the way to perfection. In this example, if a brokerage were operating at a true Six Sigma performance level with respect to BMA variance, then only three to four home assessments out of a million would exceed +/- 7.5 percent. By comparing this single metric against all other brokerages, one can begin to realize the power of Six Sigma in making determinations about brokerage performance. By employing this metric and providing feedback in a timely way to the brokers, one can begin to improve the process by doing nothing more than accurately reporting the process sigma level. Of course, one would not base revenue decisions on this sole metric.

In a more realistic example, performance of this metric would be combined with other key metrics of interest, such as quality service scores, inventory rate and days-on-market. By reporting these metrics periodically in a dashboard and scoring their relative importance, a single rating index can be calculated for the measured entity (in our example, brokers). It is through this type of systematic and deliberate approach that Six Sigma can be used to quantify performance and serve as a basis for informed decision making.

Unlike an average, a capability analysis gives a true measure of process performance by measuring defects outside customer-specified boundaries.

The DMAIC Process

Once the performance metrics are established let’s turn to how the five-step DMAIC process could be used to optimize a process that is not performing as it should. For the sake of continuity, let us assume that you are the same large broker and you have a Six Sigma Black Belt on staff whom you have assigned to optimize the BMA variance.

The project would begin in the “Define” phase. In this portion of the project, the business leader would write a business case describing the cost of the poor quality, which identifies the financial consequence from having defects, or errors, in the process, the desirable measure of success, and the project objectives. In this example, the measure of success, also known as the “primary metric,” would be the BMA variance percent (Figure 3). Project objectives can be prescribed in several ways: an arbitrary measure like 50 percent improvement, a process measure like achieving a three sigma process level, or a metric based on a well understood business measure. It is important to note that the business leader determines the primary metric and the objective before handing it off to the Black Belt to investigate.

Project selection and setup is a very important phase in the Six Sigma process, as a poorly designed and constructed project will lead to confusion, rancor and many ensuing problems as the Black Belt begins to investigate the process. In setting up the project, the business leader and Six Sigma team must reach consensus on the defect and the goals. In addition, careful consideration must also be given to the team that will work on the project. The Black Belt always leads the project, but the business leader must work with the Black Belt in assigning others to assist the Black Belt. These team members are usually subject matter experts who can lend assistance to the Black Belt as work on the project continues. The final deliverable in the Define phase is for the team to agree on the base level process through a collaborative process-mapping exercise.

Proper project selection and scoping cannot be stressed enough. A poorly defined project or one that is too large with no tangible goal will be impossible to complete and be discouraging to the Black Belt and the project team.

The “Measure” phase begins with collecting data about the process. It is here that the primary metric data is reviewed in several important ways. The first is to assess how accurate the data is (Figure 4). The success of the project is determined by this metric, and if the data behind this metric is inherently unreliable, then any improvement stemming from its use is also suspect. It is not unusual to create a more reliable measurement system, such as automated forms or some other error-proofing method, to ensure the reliability of the data.

The other main deliverable in the Measure phase is the calculation of the process capability, or process sigma discussed earlier.

Note that this step can only proceed once the reliability of the primary metric data is established.

A gage study is essential in verifying the accuracy of the primary metric. Since the success of the project depends on movement of the primary metric, the error rate associated with this metric must be measured and well understood.

The activities in the next phase, “Analyze,” rest on the shoulders of the Black Belt. It is during this phase that the Black Belt conducts statistical analysis of the data to develop possible defect scenarios.

A very important precept in Six Sigma methodology is to identify the few key inputs that can cause a defect to occur, find the optimum level for each and then monitor those levels to prevent further defects, or, at a minimum, decrease their occurrence.

The real rigor that most associate with Six Sigma occurs during this phase. Black Belts use sophisticated statistical techniques using specialized software to determine “statistical difference” among the things being tested. For instance, two agents may have standard deviation measures of .04 and .045. While it is clear that .04 is the lower measure, it is during Analyze that the Black Belt will answer the question, “Could they be the same?” If they could be the same, then even though there is a numeric difference, there is no statistical difference. If there is no statistical difference, then an improvement that is dependent on reducing variation would be ineffective. Tests of averages, medians, variation and even regression analysis all occur in the Analyze phase.

Statistical tests, such as a Test of Equal Variances and Chi-Squared Analysis, statistically prove with data the theories about the cause of the defect that are made in the Measure phase.

In this example, by comparing Chi-Square values, we see that at least one broker (D) is different from the others.

Once a competent list of defect scenarios is developed, we enter the “Improve” phase. This is the truly exciting part of the process, where the team is re-engaged.

The Black Belt reviews the three to four key inputs that have been proven to impact the primary metric with the team members. Then, through a collaborative effort, the team devises changes in the process to prevent these inputs from causing the defect. There is no right or wrong way to do this, but, if the team is carefully constructed with people knowledgeable about the process, there will be no shortage of ideas.

The final product coming out of the Improve phase is a Solution Implementation Matrix (Figure 8). In this matrix, each validated improvement is evaluated from several different aspects, such as cost to implement, ease of implementation and other success factors that the team will determine. This completed matrix is then reviewed with the business leader before formally executing any improvements.

Many improvements will require capital expense, and the business leader must make a value decision about the relative merits of each of the proposed improvements. It may be determined that while highly effective, an improvement is too costly to implement. A classic (and failed) example of this is a team that recommends adding headcount to perform some audit function. While effective, the cost associated with it is prohibitive. Only the business leader can make these decisions based on the cost and needs of the business.

Statistical analysis does not end with the Analyze phase. In the Improve phase, a pilot of the improvements, called a "Design of Experiment," is conducted and the results validated using statistics to ensure the effectiveness of the improvement.

Even though statistically validated, not all improvements will be implemented, due to business pressures such as return on investment, expense or time frame to successfully implement the change.

Control charts (shown above) continuously monitor the impact of the improvements and serve as an early warning system if a new or recurring source of variation appears.

The final step is the “Control” phase. It is during this phase that the improvements are put into place, process maps are revised to reflect the changes and the work force is trained and educated about the improvements.

Even after the new procedures are put into place, Six Sigma does not end. Rather, results are continually monitored to ensure that no new defects arise and that the old ones are sufficiently corrected (Figure 9).

Benefit of Six Sigma

Although Six Sigma is a detailed and time-consuming process if properly implemented, it is also an exciting, rewarding and successful process. No business can prosper without at least some knowledge and understanding of the key metrics that define success and periodic measurement and evaluation of their levels. It is through this structured approach that a business can be slowly changed from people making decisions based on "I think" to decisions from reasoned evaluation with data that are based on "I know."

Six Sigma at SIRVA

SIRVA uses Six Sigma to improve performance on a number of issues including, but not limited to, the ability to meet specification limits such as time or other measures, broker performance and transferee satisfaction. We also share key measurements with clients through detailed quarterly reports in the form of dashboards. These reports provide an in-depth analysis of the quality metrics that matter most to our clients' businesses. Whether your company has adopted a Six Sigma methodology or not, you'll benefit from SIRVA's use of Six Sigma as a strategic problem-solving tool that benefits all clients.